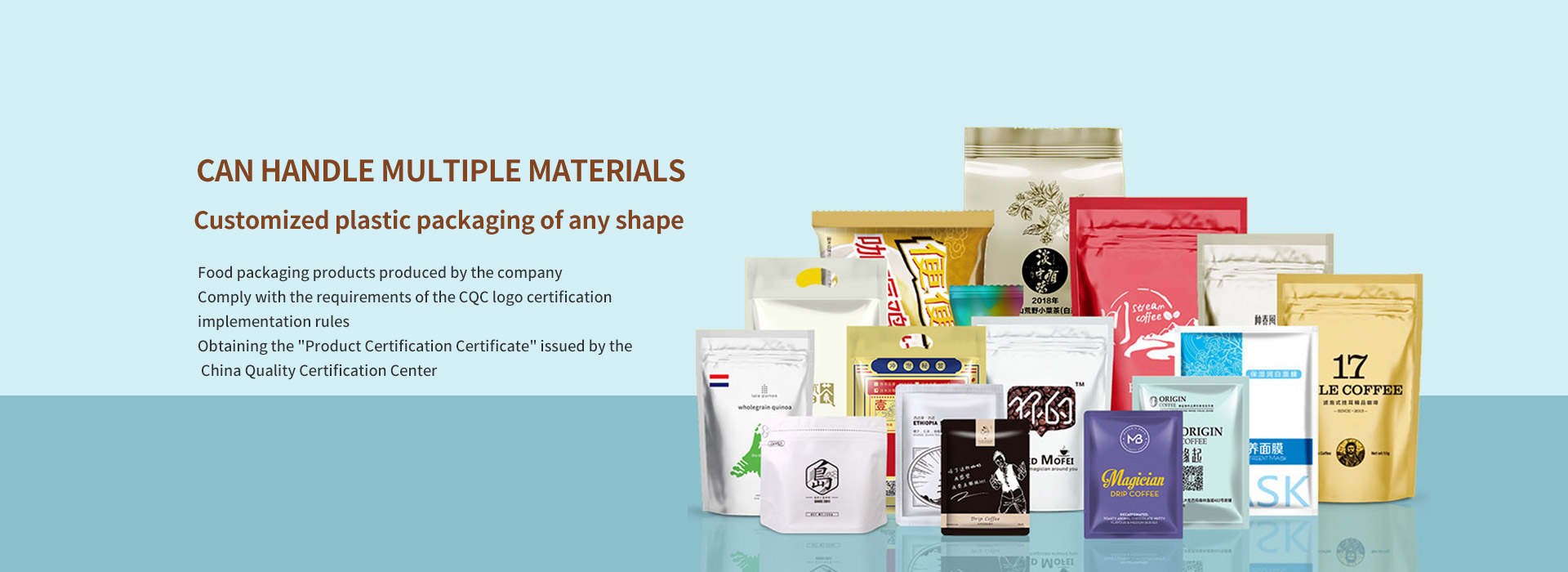

Common plastic soft packaging bags are all fixed

In the processing of plastic flexible packaging bags, problems such as breakage of the packaging bag, brittle sealing and brittle fracture often occur. This article summarizes these common questions and gives detailed answers on how plastic flexible bags appear and how to solve them.

1. Drop test, the reason for the damage of the bag?

the reason:

Plastic flexible bags sometimes have a lower heat seal strength at lower heat seal temperatures, but they also meet customer requirements, but the bags are not damaged during the drop test. In the case where the heat sealing temperature is high, although the heat sealing strength is high, the packaging bag is broken when the dropping test is performed.

This phenomenon indicates that when the heat sealing temperature is high, under the action of the heat sealing knife pressure, the inner PE film carrying the heat sealing function is melted and extruded at a high temperature to become thin and brittle, resulting in breakage during the drop test.

Solution:

When performing the bag making process, adjust the proper heat sealing temperature and pressure.In order to produce a product with excellent comprehensive performance.

Tel (We chat):+86-15020031364